Look! Junchuang Technology helps N95 mask machine industrial automation production line

Release Time:

2020-09-07 18:00

In response to the needs of the epidemic, Junchuang Technology has developed a complete set of system solutions for the automatic N95 mask machine from raw material unwinding→ mask stereotyping→ welding ear straps→ mask edge banding → mask cutting.

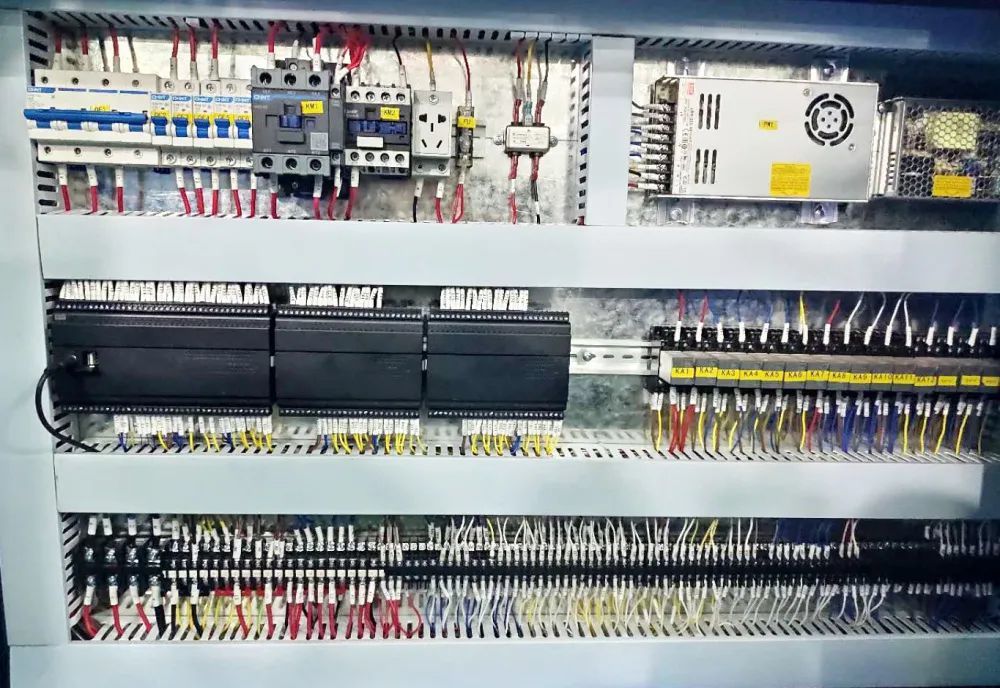

N95 mask electrical system adopts JM-60P-D model PLC controlled by 12-axis stepping/servo high-speed output control, 6-channel high-speed pulse input, built-in 4-axis electronic cam function, can 5-axis synchronization, fixed length chasing, synchronous tracking and other technical solutions, using electronic cam speed curve, accurate and high positioning, no cumulative error. The production efficiency of N95 folding three-dimensional mask can be as high as 55pcs/min, the application programming is simple, easy to understand, the operation is stable, and the accuracy of the following is less than 20 silk

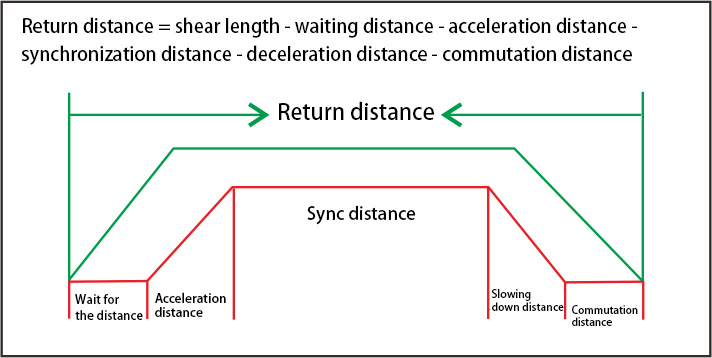

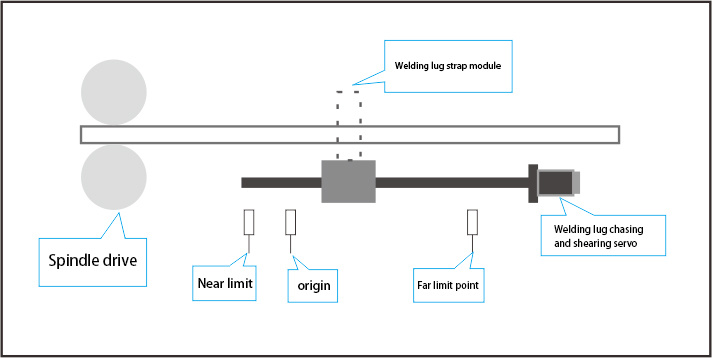

Chasing solution

The chasing and shearing system only needs to set the required waiting, acceleration, synchronization, deceleration, and commutation distance parameters to meet the customer's cam adjustment and benchmarking functions.

Shear chasing system

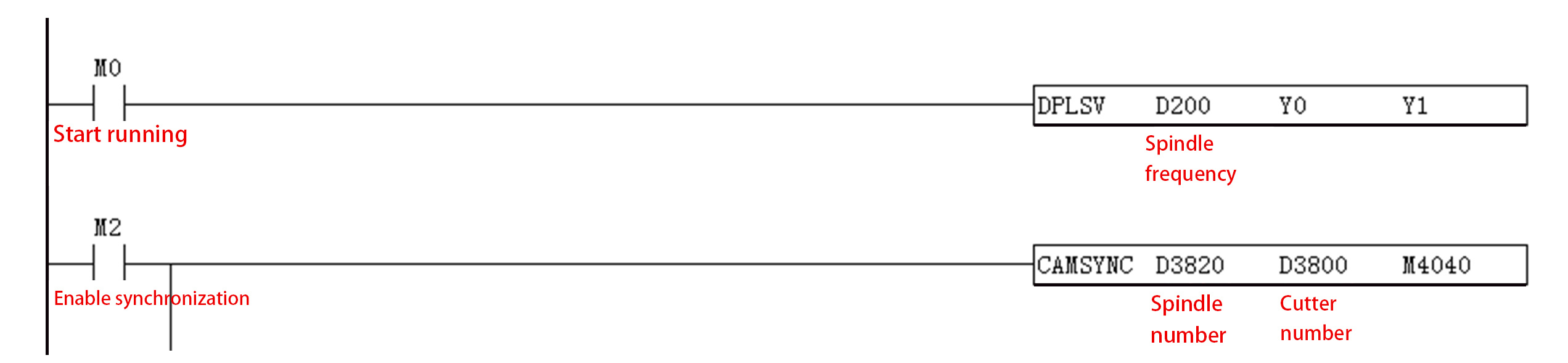

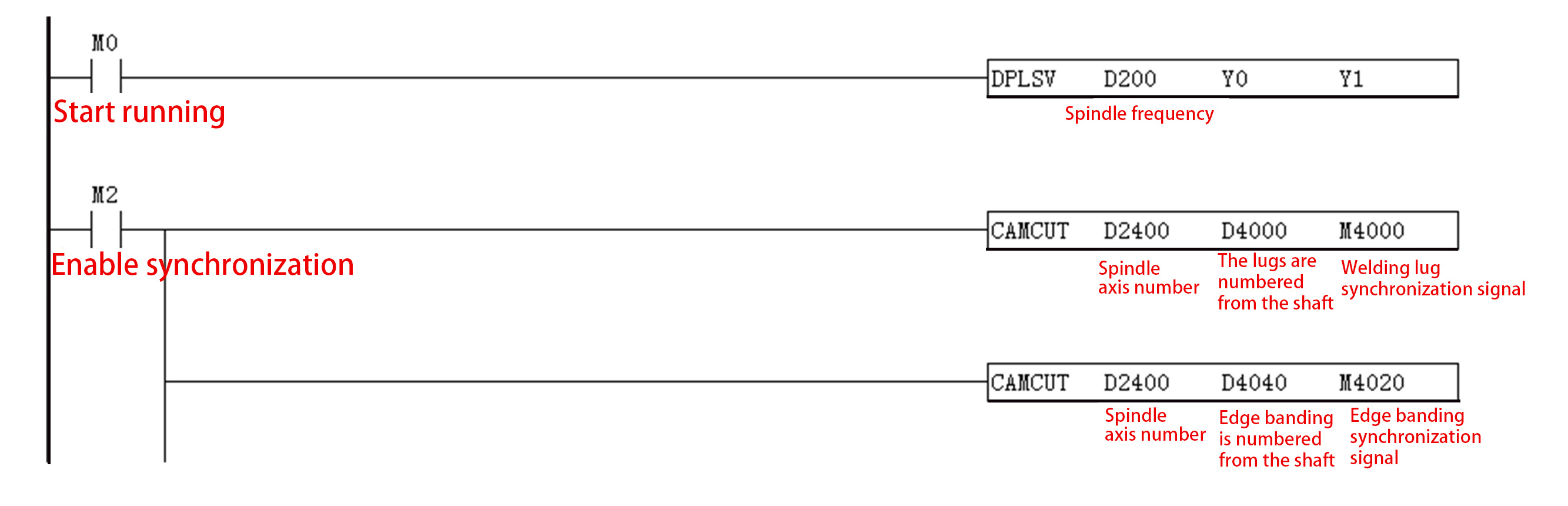

Synchronization solution

Edge banding synchronization: The electronic cam synchronization programming is simple, and the synchronous action of the edge banding shaft and the spindle can be realized by using the CAMSYNC command customized by Junchuang.

Nose bridge shaft synchronization: You can use the CAMSYNC command, or you can use the absolute displacement command to achieve synchronization, and the absolute displacement command is synchronized during the execution process by updating the target position of the nose bridge shaft in real time according to the position of the spindle.